In the news, recently, Hyne Timber has been celebrating the commencement in operations of their much anticipated new Continuous Drying Kiln (CDK) which was marked in an official ribbon cutting event held on the 8 October. See: Hyne’s Continuous Drying Kiln Officially Operating

Did you know that the research from the ARC Future Timber Hub project "Impact of continuous drying on key production and performance criteria of engineered wood structural elements" has contributed greatly to this success story?

Hyne Timber's CEO, Jon Kleinschmidt, explains this invaluable support, "This is a significant expansion including a $14.5M investment that will enable us to significantly increase production from the Mill. We have publicly announced this expansion, including the recruitment of almost 60 people. The public announcements have focused on the creation of jobs. What hasn’t been focused on but certainly remains an area deserving of recognition, is the role of the ARC Future Timber Hub, in coordinating complex and unique research and development behind the scenes."

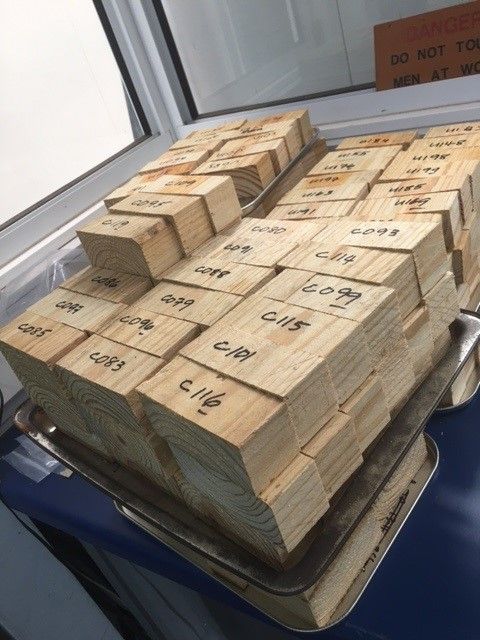

Drying timber is the "bottleneck" at Hyne Timber's Tuan Mill, consuming the most energy and time, and contributing to the highest carbon footprint in the harvesting and processing operations. CDK kilns achieve significant thermal energy efficiencies of about 20-30% and have several other advantages. However, some apprehension exists due to the perceived potential impacts of this technology on other production and performance criteria of engineered wood structural elements.

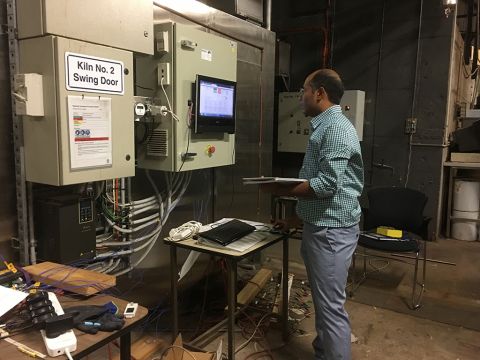

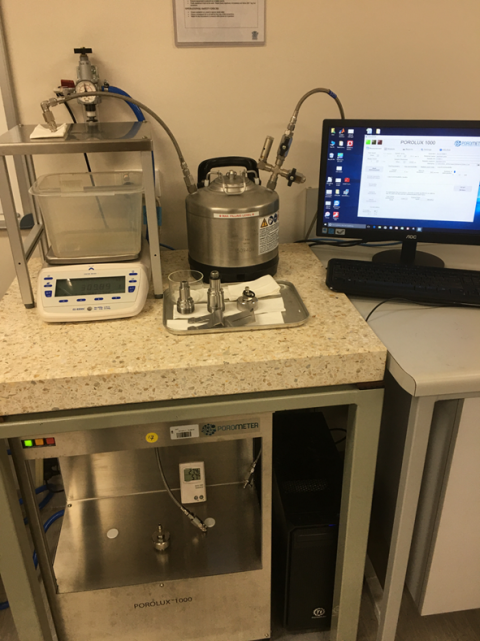

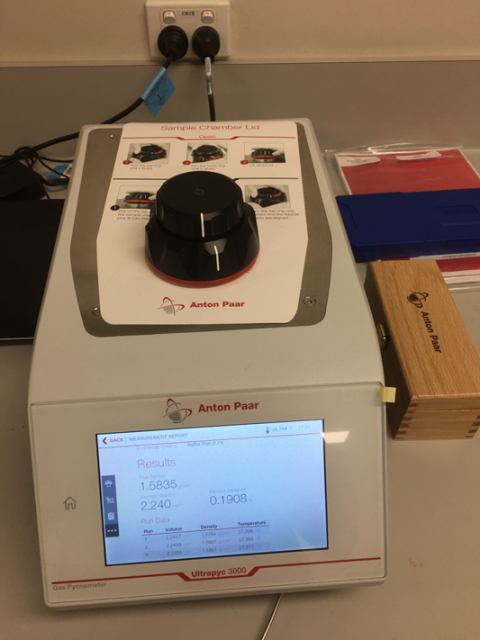

With unparalleled expertise and unique equipment designed for this project, the ARC Future Timber Hub project, led by the Forest Product Innovation team at the QLD Department of Agriculture & Fisheries (QDAF), was able to successfully identify key concerns related to the impact of CDK on crucial performance and production attributes and drying quality. A three dimensional heat and mass transfer model for predicting drying behaviour was developed for case study analysis and schedule optimisation in collaboration with School of Mathematical Sciences at Queensland University of Technology.

"The highly qualified team, combined with QDAF’s well-equipped facility, is the only group in Australasia capable of accurately reproducing Continuous Drying Kiln drying schedules for us. This has been essential in supporting us with our expansion investment," Jon Kleinschmidt said.

Hyne Timber is a founding partner of The University of Queensland's Centre for Future Timber Structures (CFTS) and the UQ led ARC Future Timber Hub. The Hub's project team, led by Dr Chandan Kumar, QDAF, is very proud to receive this appreciation from Hyne Timber. The team of dedicated and specialist experts have been able to support Hyne Timber and in turn this has affected the industry more broadly, securing and creating jobs in regional Queensland while growing Queensland’s manufacturing capability for the future.

CFTS Director, Professor Keith Crews, who attended the 8 October ribbon cutting event, has acknowledged the impact of this investment in an "In Queensland" 14 October article, Branching out: Queensland sawmill's breakthrough may help ease timber shortage.